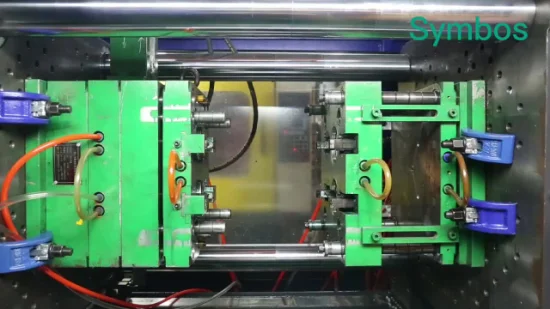

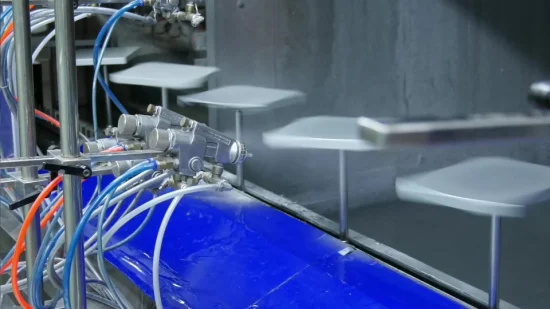

Hot Runner Flip Top Cap Mould with Cap Closing System in

Mold manufacturers produce injection mold processing and manufacturing, to sample precision plastic products abs shell F

Send your inquiryDESCRIPTION

Basic Info.

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| Roughness | Ra0.2 - Ra3.2 (Customize Available) |

| Tolerance | +/-0.005 ~ 0.1mm |

| Transport Package | EPE, Plastic Bag, Bubble Bag or Custom Package |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 100000 |

Product Description

Mold manufacturers produce injection mold processing and manufacturing, to sample precision plastic products abs shell| MOQ | 1pcs |

| Lead Time | Mold: 30 days.Mass Plastic Production: 10-25 days |

| Package | 1)pp bags + carton or wooden case2) according to customers' requirements3)negotiable |

| Payment Terms | Trade Assurance, T/T/ West Union |

FAQ

1. Are you a manufacturer or a trading company?

We are the set design, development, production, sale, and service of industry and trade-oriented enterprises,dedicate to precision CNC machining services customized for non-standard products.

2. How can I get a quote?Please offer 2D or 3D drawings (PDF/STEP/IGS/DWG...) with material, dimension, tolerance, surface treatment, quantity, and other technical requirement, etc. We will offer a quotation in 24 hours.

3. Can I get a quote without drawings?Sure, we appreciate receiving your samples, pictures, or drafts with detailed dimensions for an accurate quotation.4. Will my drawings be divulged if you benefit?No, we pay much attention to protecting our customers' privacy, and signing NDA are also accepted if needed.5. Can you provide samples for free?

Our sample is free, Freight charge only.

6. How about the lead time?

Generally, 5-7 days for samples, and 3-4 weeks for mass production.

7. How do you control the quality?

(1) Material inspection--Check the material surface and rough dimensions.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending it to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC before shipment.

8. How do I know the progress of my order?

We will offer a detailed product schedule and send weekly reports with digital pictures and videos which show the machining progress.

9. What will you do if we receive poor-quality parts?Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.