28mm Pco Neck Preform Mould

G-PLAS PRECISION MACHINERY TO MAKING PET PREFORM MOLD HAVE BEEN 30 YEARS IN NINGBO ZHEJIANG CHINA. FROM 12-CAVITY TO 96-

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | PET MOLD |

| Cavity Quantity | 48 |

| Certification | CE |

| Customized | Non-Customized |

| Neck | 28mm |

| Voulme | 600ml-650ml |

| Weight | 18g |

| Transport Package | Wooden Case |

| Specification | 2000kg |

| Trademark | G-PLAS |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 80 |

Product Description

G-PLAS PRECISION MACHINERY TO MAKING PET PREFORM MOLD HAVE BEEN 30 YEARS IN NINGBO ZHEJIANG CHINA.FROM 12-CAVITY TO 96-CAVITY HOT RUNNER AND COLD RUNNER MOLD . MAKING FOR WATER BOTTLES , JUICE BOTTLES ,

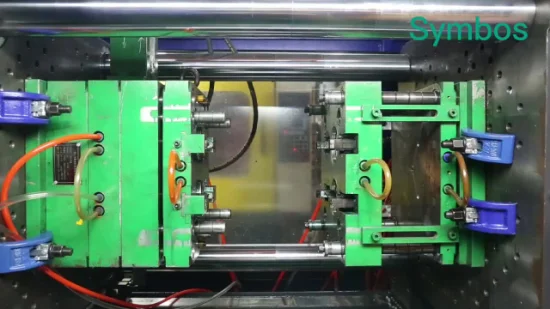

Preform mould photos

6-CAVITY HOT RUNNER BIG HEAVY GRAM PREFORM MOULD 8-CAVITY HOT RUNNER JAR PREFORM MOULD

32-CAVITY PREFORM MOULD 48-CAVITY PREFORM MOULD

Preform sample

III,preform Mould specifications

| Cavity Number | 22g Preform Length:94mm | 32g Preform Length:120mm | 42g Preform Length:130mm | |||

| Dimension (mm) | Weight (kg) | Dimension (mm) | Weight (kg) | Dimension (mm) | Weight (kg) | |

| 4(1*4) | 500*290*430 | 550 | 500*290*445 | 600 | 500*290*455 | 680 |

| 6(2*3) | 430*370*400 | 760 | 430*370*415 | 850 | 430*370*425 | 900 |

| 8(2*4) | 490*370*435 | 810 | 490*370*450 | 900 | 490*370*460 | 970 |

| 12(2*6) | 630*370*435 | 1020 | 630*370*450 | 1100 | 630*370*460 | 1180 |

| 16(2*8) | 750*370*480 | 1240 | 750*370*495 | 1350 | 750*370*505 | 1450 |

| 24(3*8) | 830*440*500 | 1880 | 830*440*515 | 1950 | 830*440*525 | 2060 |

| 32(4*8) | 830*580*515 | 2360 | 830*580*530 | 2550 | 830*580*545 | 2600 |

| 48(4*12) | 1065*580*525 | 2930 | 1065*580*540 | 3050 | 1065*580*555 | 3150 |

| 72(6*12) | 1140*830*560 | 4320 | 1140*830*575 | 4450 | 1140*830*580 | 4600 |

Note:Above specifications are subject to change without prior notice.Dimesion means Height x Width x Thickness

| Name | Description | ||||

| Products' info we need to make quotation | Clear Pics/material/size/weight/wall thickness/targetting quantity and etc. | ||||

| Mould Material | 45#,50#,P20,H13,718,2738,NAk80,S136,SKd61 etc | ||||

| Mould Base | LKM,HASCO ect . | ||||

| Cavity | Multi | ||||

| Runner | Hot/cold | ||||

| Mould Design | 3D/2D Drawing | ||||

| Design Days | 3 days | ||||

| Design Software | UG,PROE,CAD,CAE,CAM,CAXA ect | ||||

| Plastic Material | PP,PC,PS,PE,PU,PVC,ABS,PMMA ect | ||||

| Mould Life | 300,000-3,000,000 shots | ||||

| Injection System | Pin-point-gate | ||||

| Polish System | Mirror Polish | ||||

| Payment | 30% of Deposit by T/T,70% of Balance by T/T | ||||

| Delivery Time | 15-60days | ||||

| Specification | Depends on customers requirements | ||||

| Business Step | |||||||

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed | ||||||

| ↓↓↓ | |||||||

| 2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get | ||||||

| ↓↓↓ | |||||||

| 3.Negotiation | The quality ,price ,material,delivery time .payment item.ect | ||||||

| ↓↓↓ | |||||||

| 4.Mould Design | 3-5 days for mould and product 3D/2D drawing design | ||||||

| ↓↓↓ | |||||||

| 5.Mould | According to customers' request to build the mould.Before make the mould .we send mould design to customer approval first . Mould will be usually finished in 25-60 days | ||||||

| ↓↓↓ | |||||||

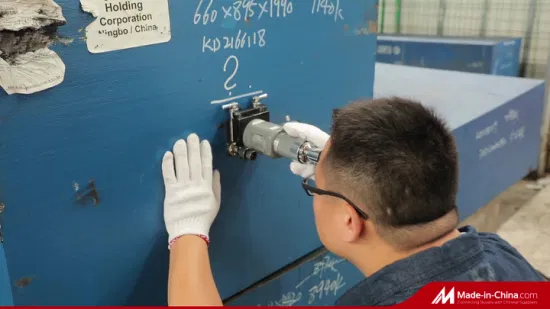

| 6.Mould Testing | When moulds are finished,we will test the moulds to check it satified consumers' needs.And we will send samples for consumers' reference. | ||||||

| ↓↓↓ | |||||||

| 7.Sample shoot | If the first sample come out is not satisfied customer .we modify the mould and until meet customers satisfactory | ||||||

| ↓↓↓ | |||||||

| 8.Delivery | Delivery goods by sea or by air ,according customers requirement | ||||||

spare parts follow machine and working CNC MACHINE

SHIPPING LINE FROM FACTORY NINGBO TO OVERSEA

FAQ

Q1: Are you a factory or trading company?

A: We are a factory .

Q2: Where is your factory located?

A: Our factory,near Shanghai, located in Ningbo,China

Q3: what is your trade term?

A: normally FOB NINGBO, if customer country requires, also can accept L/C at sight.

Q4: what is your payment term?

A:50% down payment against order confirmation, 50% balance payment prior shipment.

Q5: Have blow machine 100% assemnled well in stock?

A: No. All blow machine will be assembly produced according to your order.

Q6: what is your delivery time?

A: usually in 60days, depends on your projects.

Q7: what about installing in customer factory?

A: after machine arrived at your factory, please prepare water, electric,air and preform, then we will arrange engineer to install machine and train your workers, the longest time to free install shall be in one week, you should afford engineer air tickets, food, hotel,transport.

Q8:guarantee time?

A: one guarantee, not man-made.

Related Products

-

![Customized Mold Base/Plastic Injection Mould/Automobile Deflector/High Pressure Die Casting]()

Customized Mold Base/Plastic Injection Mould/Automobile Deflector/High Pressure Die Casting

-

![Household Appliances Acrylic Multi Cavity Mould Electrical Plastic Injection Mold]()

Household Appliances Acrylic Multi Cavity Mould Electrical Plastic Injection Mold

-

![Nylon Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds]()

Nylon Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds

-

![Direct Factory Customized High Precision 8 Cavities Juice Bottle Cap Plastic Cap Mould]()

Direct Factory Customized High Precision 8 Cavities Juice Bottle Cap Plastic Cap Mould