Automobile Car Spare Party Plastic Mold

Overview Auto Car Bumper Parts Plastic Mold Auto Car Mold belong to high precision Plastic Injection Mold. Auto Car Mold

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Auto Parts Plastic Mold |

| Application | Car |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TUV |

| Standard | DME |

| Customized | Customized |

| After-sales Service | with in 24 Hours Online Guidance |

| Hydraulic Cylinder | Taiwan Brand |

| Mould Cycle Time | 160s |

| Ejection System | Ejector Pin & Plate |

| Mould Guarantee | 1 Year |

| Pallet Loading Ability | Well Standard |

| Mould Life | More Than 500K Shoots |

| Mould Delivery Time | 150 Days |

| Mould Tooling Precision | 5-Axis Tooling Machine |

| Cooling System | Beryllium-Bronze Insert |

| Hot Runner System | Yudo, Mold Master, Chinese Brand |

| Mould Steel for Basement | S50c |

| Mould Treatment | Nitridation, Quencher, Heat-Treated, Pre-Hardening |

| Mould Steel for Core | HP20, H718, 2738 |

| Transport Package | Wooden Case |

| Specification | 2000x1000x700mm |

| Trademark | Rongdu Mould |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 500 Sets Mould Annually |

Product Description

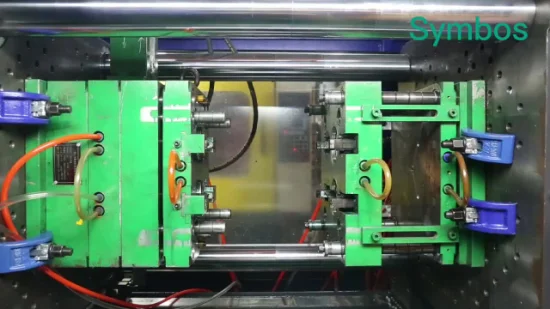

Auto Car Bumper Parts Plastic Mold

Auto Car Mold belong to high precision Plastic Injection Mold. Auto Car Mold needs scientific mold structure. Rongdu Mould is a big company, which owns a good design team, high precision tooling center, experienced mold workers, strictly mold quality control system. And we have cooperated with many auto company and won a high reputation from them.Product Name: Auto Car Bumper Parts Plastic Mould

Product Size: 2000*1000*700mm

Product Weight: 25KG Plastic Material: ABSDesign Program: NX(UG), Auto CAD, Solid Works

Mould Size: 2500*1600*1100mm

Mould Cavity: Single Cavity Mould Steel for Cor/cav: HP20,H718,2738, S136 Mould Steel for Slider/Insert Block: HP20,H718,2738, S136 Mould Steel for Basement: S50C, HP20Injection System: 22 Tips Hot Runner SystemGate Type: Needle Valve Gate TypeHot Runner System: Chinese Brand, YUDO Brand, Mold Master BrandCooling System: Beryllium-Bronze Insert & Water CoolingEjection System: Ejection Plate & PinMould Surface Treatment: Texture or High Gloss PolishingHydraulic Slider: JUNFAN made in TAIWANMould Spare Part: DME or HASCO StandardMould Tooling Tolerance: ±0.1mm

Mould Cycle Time: 160SMould Life: 1 Million Shoots Mould Guarantee: 1 year Mould Deliver Time: 150 Days

Product Description

| Product Name | Auto Car Bumper Parts Plastic Mould |

| Product Size | 2000*1000*700mm |

| Product Weight | 25KG |

| Cavity Number | Single Cavity |

| Plastic | ABS |

| Design Program | NX(UG), Auto CAD, Solid Works |

Mould Description

| Mould Size | 2500*1600*1100mm |

| Mould Cavity | Single Cavity |

| Mould Steel for Cor/cav | Nitrided & Heat-Treated & Hardened Steel HP20,H718,2738 |

| Mould Steel for Slider/Insert Block | Nitrided & Heat-Treated & Hardened Steel HP20,H718,2738 |

| Mould Steel for Basement | Nitrided & Heat-Treated & Hardened Steel S50C, S45C |

| Mould Raw Material Treatment | Nitridation, Quencher, Heat-Treated, Pre-Hardening |

| Injection System | 22 Tips Hot Runner |

| Hot Runner System | YUDO, Mold Master, Chinese Brand |

| Cooling System | Beryllium-Bronze Insert & Water Cooling |

| Ejection System | Ejection Plate & Pin |

| Mould Surface Treatment | Texture or High Gloss Polishing |

| Hydraulic Slider | JUNFAN made in Taiwan |

| Mould Spare Part | DME or HASCO Standard |

| Mould Tooling Tolerance | ±0.1mm |

| Mould Cycle Time | 160S |

| Mould Life | 500K shoots |

| Mould Guarantee | 1 year |

Mould Delivery Description

| Mould for T1 | 130 days |

| Mould Deliver Time | 150 days |

| Mould Installation | Fixed |

| Mould HS CODE | 8480719090 |

| Package | Wooden Case, mould would be Fixed inside |

| Transportation | By Air or By Sea |

| Payment | T/T, CIF |

Company Profile

1. Background

Rongdu Mould is one of the Pioneer for plastic injection mould manufacturer. The Originator of us have making mould since 1985 year and accumulated abundant experiences. So we are specialized for manufacturing all kinds of plastic injection mould, especially for AUTO CAR MOULD, plastic pallet Mould, Crate Mould, Plastic Chair Mould, Industrial Waste Bin Mould, Plastic Warehouse Mould etc.

Rongdu could manufacturer more than 600 sets of plastic mould annually, including 50 sets of CAR MOULD, like car bumper mould, car lamp mold, car rearivew mould, instrument panel mold etc.

"Making Mould More Valuable " is our final achievement. We focus on the MOULD QUALITY & DELIVERY TIME, providing stable mould within shortly time for each customer. So Rongdu Mould won good reputations from our old regular customer, and become one of leading for AUTO CAR MOULD MANUFACTURER.

2.Advantages

A. Rongdu have Strong Design Team

For every new mould project, we would have a meeting to discuss all detail information, After product design will be confirmed, we would make the mould design and Mold Main Flow Analysis, in order to give customer reasonable suggestions and find best solution.

B. Rongdu have strict Mould Testing Standards

a. We would test every mould raw material, ensure the mould raw material quality.

b. We would checkout the mould Tooling processing, in order to make the each part of the mould could have precising dimension.

c. Our Assemble Mould Worker have more than 10 years working experience, we are familiar with all details.

C. Rongdu have Fast Mould Delivery Ability

Mould prompt be shipment is our most advantage, we take high attention and responsibility for customer demand, shipping each set mould timely to customer country.

3.Service

Rongdu mould not only sale the mould to customer, we pay highly attention Pre- & after- service. We would discuss with customer together, like product structure, analysis demould feasibility, analysis mould main flow. And we would have a meeting before the mould manufacturing, in order to support more valuable suggestions for our customer.

FAQ

-What Products Can You Provide?

Rongdu mainly manufacture:1111 Single-sided Nested Pallet Mold with Nine-leg ; 1210 Single-sided Nested Pallet Mold with Nine-leg ; 1210 Single-sided Grid Pallet Mold with Nine-leg on bottom;1210 Single-sided Flat Pallet Mold with Nine-leg ; 1010 Double-sided Grid Skid type Pallet Mold; 1111 Double-sided Grid Window type Pallet Mold;1111 Double-sided Grid Skid type Pallet Mold; 1210 Grid Skid type Pallet Mold; 1210 Single-sided Grid Pallet Mold;1210 Single-sided Flat bottom Skid type Pallet mold; 1080 Window type Pallet Mold; 1080 Grid Skid type Pallet Mold;1212 Grid Window Pallet Mold; 1311 Grid Skid with ten Steel-Insert Pallet Mold; 1311 Double-sided Grid Pallet Mold;1412 Double-Sided Grid Pallet Mold; 1412 Double Flat Pallet mold; 1513 Double-sided Grid Pallet Mold; 1513 Double-sided Flat Pallet Mold, etc.;5L, 15L Medical Garbage Mold; 30L, 50L, 100L, 120L, 240L, 360L, 600L Industrial Garbage Mold; 40L Two-Color sorting Garbage Mold etc. ; Fruit and Vegetable Crate mold; Bread Bucket mold; Clothing collection Container Mold and other Turnover Box Mold; Large Pallet Box Mold.

-How Long Can I Get The Feedbacks After We Sent The Inquiry?

We will reply you within 24 hours in working day.

-What Application Fields Are Your Products Mainly Involved In?

Plastic pallets are suitable for chemical, petrochemical, food, aquatic products, feed, clothing, making, shoes, electronics, electrical appliances, port, dock, catering, bio-pharmaceutical, mechanical hardware, automobile manufacturing, petrochemical, stereo storage, logistics and transportation, warehouse handling, storage shelves, auto parts, beer and beverage, textile printing and dyeing, printing and packaging, logistics station and other industries.

-Can You Make Customized Products?

Yes, we mainly make customized products. We develop and produce products based on drawings or samples provided by customers.

-What Is The Production Capacity Of Your Company?

We have our own production flow from the procurement of steel preparations to five-axis milling machine, CNC tooling machine, lathe machine, fine carving machine, electric discharging machine, graphiting machine, slow wiring machine, wire cutting machine, etc., and then to mold installation.

-What Is The Payment Method?

We would confirm the transaction method with you, we generally adopt the FOB method. We usually pay 50% of the advance payment first, and then pay the balance before shipping.

Related Products

-

![Custom Made Mould Base Frame Plate High Precision Tooling Maker Plastic Injection Mould for Auto Part Home Appliance Medical instrument Structure Parts]()

Custom Made Mould Base Frame Plate High Precision Tooling Maker Plastic Injection Mould for Auto Part Home Appliance Medical instrument Structure Parts

-

![Factory Mold Production of Industrial Injection Molding Parts Housing Electronic Originals]()

Factory Mold Production of Industrial Injection Molding Parts Housing Electronic Originals

-

![Nylon Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds]()

Nylon Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds

-

![Chinese PA Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds]()

Chinese PA Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds